The RPR Induction Technology works by fast transfer of energy to the steel substrate, as a result securing a controlled heating of the surface and fast removal of most types of coatings.

Coating Removal On Storage Tanks – The RPR Induction System for coatings removal is highly suitable for fast and efficient stripping of large surfaces or for inspection of weld seams in storage tanks. Experience from work on tank bottoms have shown that thick glass-fiber (5-6 mm) can be removed with stripping rates up to 10-12 m2/hr. while thinner traditional painting systems can be removed in rates up to 35 m2/hr.

Not only does the RPR Induction system yield great economic benefits like higher stripping rates and minimal waste disposal, but it is also enables environment – and operator friendly operation.

ECO Innovation – GreenTank

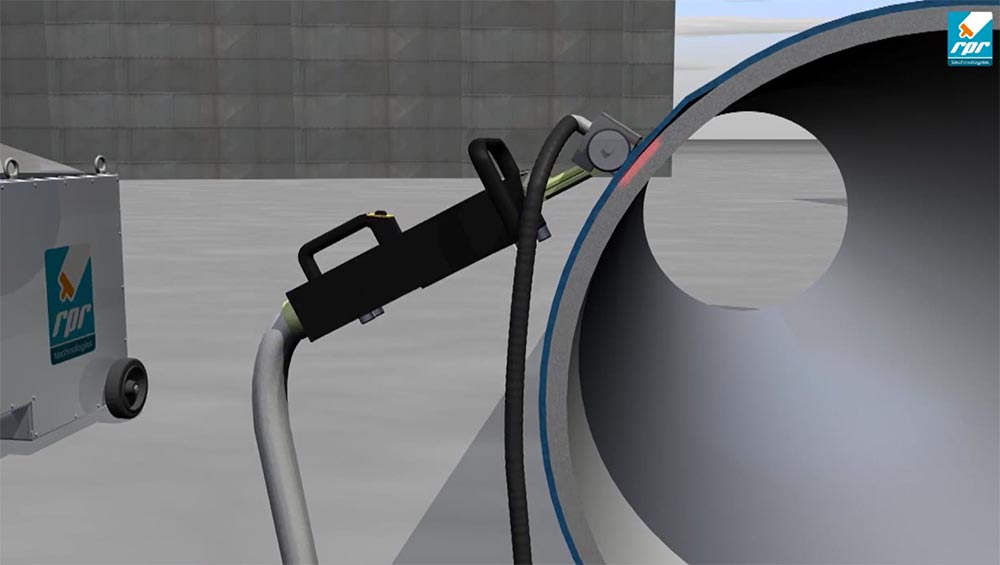

Resulting from a project called Green Tank, co-funded by the European Commission; RPR Technologies now offers optimized solutions for coatings removal in storage tanks. Combining a patented induction technology and elements of semi-automatic platforms, the RPR Induction Coatings Removal System has proven to be twice as efficient as other methods.

Mounted to an electric trolley with vertical support, the system is ideal for removal of difficult coatings on tank floors and the lower wall section, securing a consistent result and alleviating workload for the operators. After heating the coating is scraped off in stripes that is easily collected and transported for disposal, offering considerable environmental savings in logistics and waste handling.

Why Use RPR Technologies

“Twice as fast as sandblasting”

Statement from a main contractor to the industry.

HIGHER STRIPPING RATES

Especially effective in removing floor- and inner-wall lining resulting in shorter down time.

MINIMIZED WASTE DISPOSAL

Above all, this method does not add any grit or water media that needs transport, processing and disposal.

OPERATOR FRIENDLY

- No high pressure

- Quiet operation

- No air-born dust emissions

- Less protective gear needed

Most importantly – the Coating Removal On Storage Tanks is safe for the operator or nearby workers carrying out other maintenance or inspection work.

ENVIRONMENT

- Easy waste containment.

- Minimal risk of local contamination.

- About 75% less energy consumption compared with traditional methods.

- Use of RPR Induction for coatings removal gives no grit or water deposits. Therefore, transport cost and emissions is reduced to a minimum.

REFERENCES

♦ SHELL

♦ PETRONAS

♦ COSMO OIL

♦ CONOCO OIL/PHILIPS

♦ BP

♦ TOTAL

♦ PREEM

♦ PETROBRAS

♦ STATOIL

Coating Removal On Storage Tanks

Cost Efficient | Fast Removal | No Water / Grit | Safe Operation | Shorter Down Time | Silent

– The world’s fastest, safest and cleanest method for removing paint and coating from steel surfaces.

Videos

RPR Buggy video on Petronor refinery

RPR Induction Disbonder used on coatings removal in storage tanks of the refinery of Petronor/Repsol in Bilbao. Instant Induction Heat break the bonding of the tank bottom lining. Motorized buggy provides high quality consistent rate of removal.

Tank Lining in Trieste, Italy

Remove coating and paint fast and clean with induction thechnology. Harmless for operators and nature.

Protect the environment!

Removal of Belzona 1391 Hard Ceramic Coating

Kuurman removes Belzona 1391 hard ceramic coating average thickness 20-30 mm (800 – 1200 mils) within seconds. The coating is hard to remove with current treatments and cost a lot a energie and money. Kuurman knows a way to remove this difficult and thick coating.

Kuurman way is FAST, LOCALIZED, CLEAN and SAFE for ENVIRONMENT!

Coating Removal on a Crude Oil Storage Tank of PDO, Oman

Quick removal of difficult and thick coating GRE with induction heat from the induction disbonder of RPR Technolgies.

Stripping Exterior and Interior Rubber Lining off Railroad Tank Wagon

4 mm rubber is removed from this railroad tank wagon at high speed.