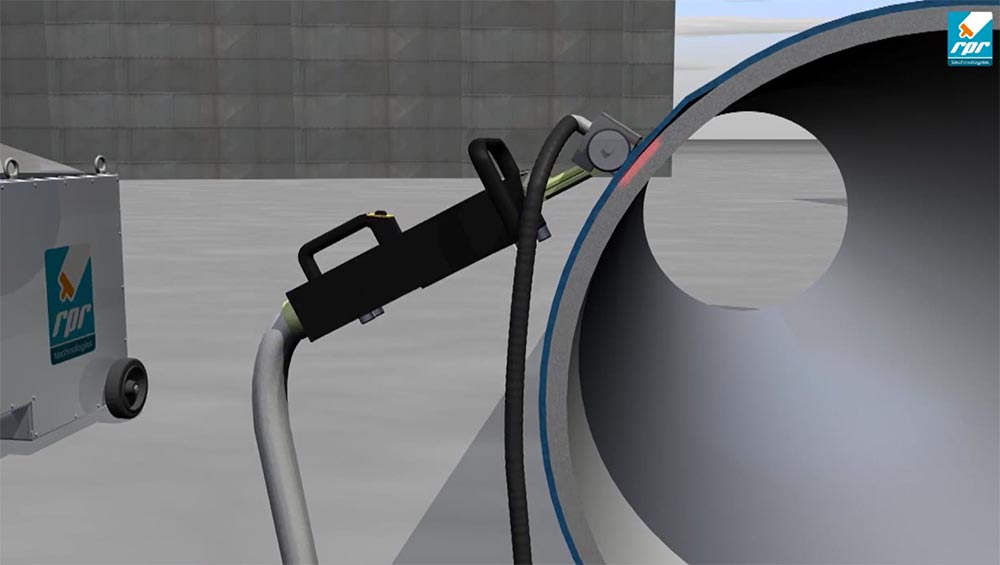

The RPR Induction Technology works by fast transfer of energy to the steel substrate, as a result securing a controlled heating of the surface and fast removal of most types of coatings.

Coating Removal On Steel Structures – Compared with conventional coatings removal methods using grit or water, the patented RPR Induction System for coatings removal offers many advantages. Old coatings on steel structures often contain hazardous components like Lead, PCB or Asbestos, requiring stringent containment measures.

Using the RPR induction System offers a safe, fast and silent removal process. The coating comes off easily in strips or pieces that can be bagged for disposal without risk of contamination to air, ground or water.

Typical areas of use are: bridges, buildings, mines, paper mills, industrial plants, power plants, etc.

The induction heads are available in many shapes and sizes for use in confined spaces. Coatings with thickness up to 20-25 mm are removed quickly and efficiently, including epoxy, rubber, fiberglass, PFP’s, etc. Robotics or tailored automatic solutions can be offered upon request.

Why Use RPR Technologies

– The world’s fastest, safest and cleanest method for removing paint and coating from steel surfaces.

HIGHER STRIPPING RATES

Depending on accessibility, coating type and thickness, removal rates of up to 30 m2/hr can be achieved.

HAZARDOUS COATING

Toxic and hazardous coating containing e.g. PCB, Lead or Asbestos comes off easily and safe in strips or flakes for easy collection, containment and disposal.

MINIMIZED WASTE DISPOSAL

In contrast to use of grit or UHP, the method does not add any grit or water media that needs transport, special waste processing and disposal.

OPERATOR FRIENDLY

- No high pressure

- Quiet operation

- No air-born dust emissions

- Less protective gear needed

Most importantly – the RPR Technologies coatings removal system is safe for the operator or nearby workers carrying out other maintenance or inspection work.

ENVIRONMENT

- Easy waste containment.

- Minimal risk of local contamination.

- About 75% less energy consumption compared with traditional methods.

Above all, use of RPR Induction for coatings removal gives no grit or water deposits. Therefore, transport cost and emissions is reduced to a minimum.

REFERENCES

♦ KAEFER

♦ CAPE

♦ YOKOGAWA BRIDGE CORP

♦ JAPAN BRIDGE CORP

♦ E.ON

♦ IRIS

♦ TIEFENBACH

Coating Removal On Steel Structures

Cost Efficient | Fast Removal | No Water / Grit | Safe Operation | No air-born dust | Silent

Videos

Coatings removal, Clean and Easy with RPR Technologies

Now showing the cleanest and fastest way to remove paint from steel surfaces.

No dust, no noise!

Minidisbonder, Paint and Coatings Removal with Induction Technology

Our newest ligth weight induction tool to easily remove coated steel strucures.

RPR Induction Disbonder Removing Coating Very Fast on Steel Construction

Two operators working at good pace removing thick old coating from steel construction using our novel induction technology.

Stripping century Old Paint on the Eiffel Tower, Paris

Trial to test the feasability of using the RPR Induction Disbonder when refurbishing the Eiffel Tower.

Induction for Coatings Removal, Buildings

The RPR Induction machine is specially designed to cleanly, safely and quickly remove thick and difficult coatings from steel surfaces.