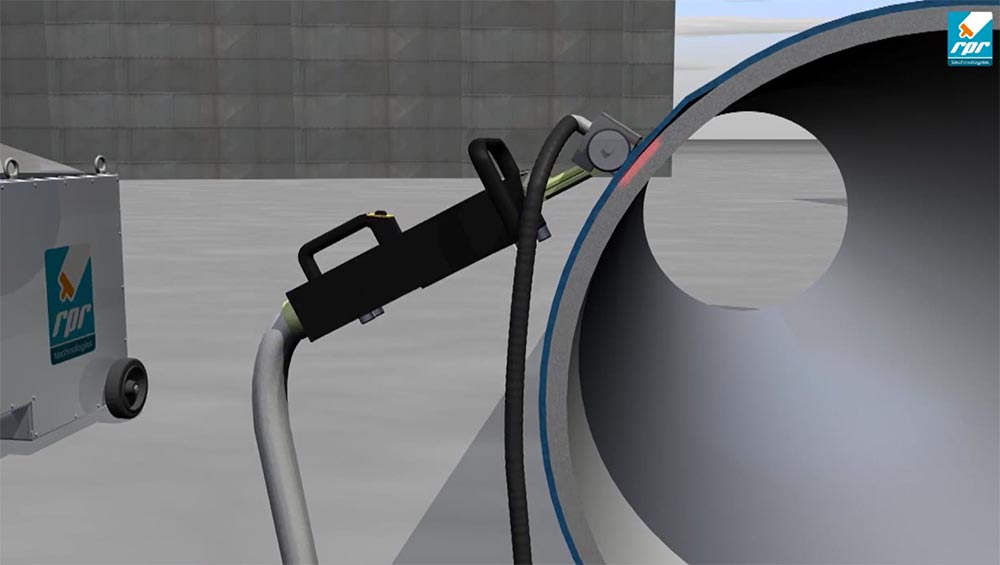

The RPR Induction Technology works by fast transfer of energy to the steel substrate, as a result securing a controlled heating of the surface and fast removal of most types of coatings.

Coating Removal In Offshore – Compared with conventional coatings removal methods using grit or water, RPR Induction Disbonding System offers many advantages such as a safe, fast and silent removal process. The coating comes off easily in strips or pieces that can be bagged for disposal without risk of contamination to air, ground or water. It easily removes coatings with thickness up to 25 mm.

Due to the fast removal process; a significant reduction in down-time can be achieved.

Working radius is up to 100 m, allowing significant versatility and a virtually silent process.

Areas of use are on decks, gangways, water tanks, helicopter-decks, in fire-protected areas like blast-walls and many more.

Typical use in the offshore sector is removal of anti-skid, tank linings, PFP’s (e.g. Chartek) and other thick coatings.

Why Use RPR Technologies

– The world’s fastest, safest and cleanest method for removing paint and coating from steel surfaces.

HIGHER STRIPPING RATES

Depending on accessibility, coating type and thickness, removal rates of up to 30 m2/hr. can be achieved.

HIGH DURABLE/THICK COATINGS

Ideally used for fast removal of high durable coatings (e.g. Epoxy) on gangways and heli-decks and on surfaces coated with up to 15 mm PFP (Passive Fire protection) such as Chartek.

MINIMIZED WASTE DISPOSAL

The method does not add any grit or water media that needs transport, special waste processing and disposal.

OPERATOR FRIENDLY

- No high pressure

- Quiet operation

- No air-born dust emissions

- Less protective gear needed

Most importantly – the RPR Technologies coatings removal system is safe for the operator or nearby workers carrying out other maintenance or inspection work.

ENVIRONMENT

- Easy waste containment.

- Minimal risk of local contamination.

- About 75% less energy consumption compared with traditional methods.

- Far less transport cost and emissions due to no grit and water deposits.

REFERENCES

♦ CONOCO/PHILIPS BP

♦ PETRONAS

♦ SHELL

♦ STATOIL

♦ ELF

♦ PETROBRAS

♦ PEMEX

♦ BLUEWATER

♦ MAERSK

♦ BILFINGER

♦ KAEFER

♦ MUEHLHAN

♦ CAPE

Coating Removal In Offshore

Cost Efficient | Fast Removal | No Water / Grit | Safe Operation | Silent

Videos

Removing Thick Antiskid Deck Coating, North Sea Oil Rig, Stord

The Induction Disbonder from RPR Technologies is using controlled heat, to break the bonding and lets you remove the thick antiskid coating easy.

Typical offshore job on for instance helicopter decks.