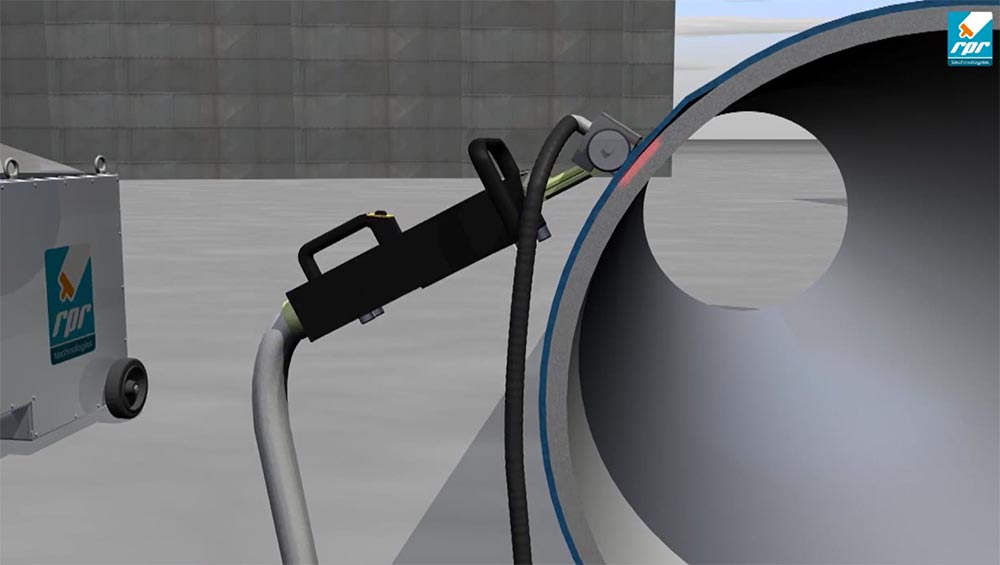

The RPR Induction Technology works by fast transfer of energy to the steel substrate, as a result securing a controlled heating of the surface and fast removal of most types of coatings.

Coating Removal On Ships – Typically, on ships and marine vessels the RPR Induction System is used for coatings removal of anti-skid systems, tank lining, thick coating on ship hulls (e.g. icebreakers), ship deck, car deck, heli-decks, fire protective coatings (PFP) and more.

Coatings removal with RPR is cost effective and does not produce additional grit or water waste and above all offers a great potential for logistical and environmental savings.

Coating removal work can be done even at sea without hindering operations, inspection or other maintenance work. The coatings is removed easily in strips or pieces that can easily be put into waste bags for disposal without risk of contamination to air, ground or water.

Working radius from the main unit is up to 100m, allowing a flexible and efficient operation. Furthermore, its patented safety features eliminates the risk of overheating the steel, being approved for use even on live oil- and gas pipelines.

Why Use RPR Technologies

– The world’s fastest, safest and cleanest method for removing paint and coating from steel surfaces.

HIGHER STRIPPING RATES

Reduced docking time or optional to even carry out work at sea without disrupting normal operations.

MINIMIZED WASTE DISPOSAL

In contrast to use of grit or UHP, the method does not add any grit or water media that needs transport, processing and disposal.

OPERATOR FRIENDLY

- No high pressure

- Quiet operation

- No air-born dust emissions

- Less protective gear needed

Most importantly – the RPR Technologies coatings removal system is safe for the operator or nearby workers carrying out other maintenance or inspection work.

ENVIRONMENT

- Easy waste containment.

- Minimal risk of local contamination.

- About 75% less energy consumption compared with traditional methods.

- Use of RPR Induction for coatings removal gives no grit or water deposits. Therefore, transport cost and emissions is reduced to a minimum.

REFERENCES

♦ US NAVY

♦ SPANISH NAVY

♦ PAKISTAN NAVY

♦ FRENCH NAVY

♦ SAMSUNG HEAVY INDUSTRIES

♦ MAERSK

♦ BLUEWATER

Coating Removal on Ships & Marine

Cost Efficient | Fast Removal | No Water / Grit | Safe Operation | Reduced Docking Time | Silent

Videos

Coating Removal Landskrona Shipyard

Very hard antiskid deck coating on the deck of aircraft carrier is easily removed with RPR equipment.