The RPR Induction Technology works by fast transfer of energy to the steel substrate, as a result securing a controlled heating of the surface and fast removal of most types of coatings.

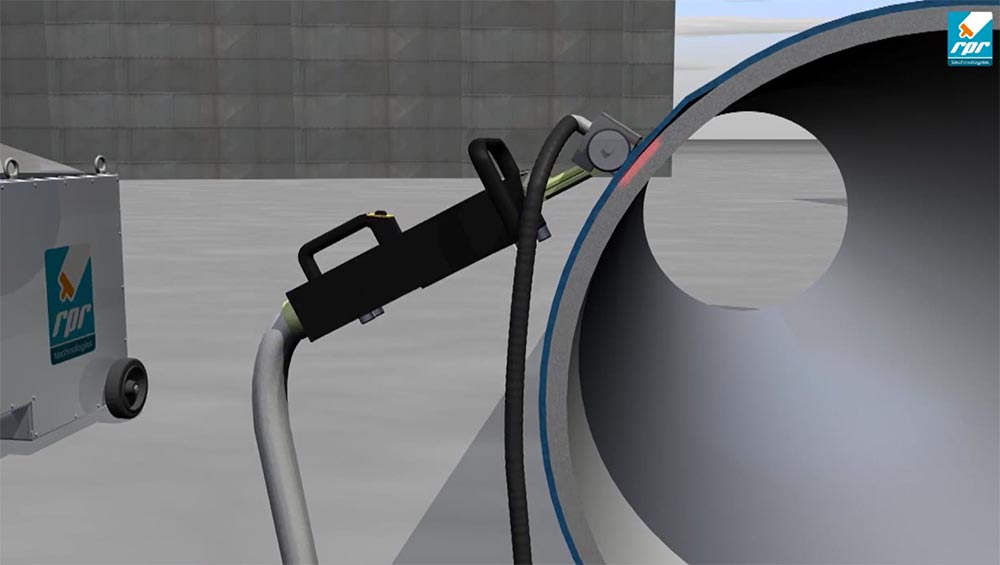

Coatings Removal On Pipelines – The patented RPR Induction System for coatings removal has proved to be very effective on pipes and live pipeline projects around the world. It efficiently and safely removes coatings such as Coal Tar, Ebonite, 3LPE/3LPP, rubber and other tough linings with thickness up to 30 mm.

Coatings removal with RPR Technologies is cost effective and does not produce additional grit or water waste, yielding great potential for savings in logistic handling, especially in remote areas.

The coatings is removed easily in strips or pieces that is easy to put in waste bags for disposal without risk of contamination to air, ground or water.

Working distance from the main unit is up to 100m that allows a flexible and efficient operation. RPR has developed a patented solution that eliminates the risk of overheating the surface when using the induction system on steel. This has been a prerequisite in the process of successfully receiving approval for use on live oil- and gas pipelines.

Why Use RPR Technologies

– The world’s fastest, safest and cleanest method for removing paint and coating from steel surfaces.

HIGHER STRIPPING RATES

Especially effective in removing tough coatings with thickness up to 30 mm.

NO DOWN TIME

Most noteworthy, there will be no downtime and therefore it can be used continuously on live pipelines.

MINIMIZED WASTE DISPOSAL

Above all, this method does not add any grit or water media that needs transport, processing and disposal.

OPERATOR FRIENDLY

- No high pressure

- Quiet operation

- No air-born dust emissions

- Less protective gear needed

Most importantly – the RPR Technologies coatings removal system is safe for the operator or nearby workers carrying out other maintenance or inspection work.

ENVIRONMENT

- Easy waste containment.

- Minimal risk of local contamination.

- About 75% less energy consumption compared with traditional methods.

- Use of RPR Induction for coatings removal gives no grit or water deposits. Therefore, transport cost and emissions is reduced to a minimum.

REFERENCES

♦ BP

♦ AGR MONGSTAD

♦ ENBRIDGE PIPELINE

♦ PTT THAILAND

♦ ROSEN GROUP

♦ GASUNIE HOLLAND

Coatings Removal On Pipelines

Cost Efficient | Fast Removal | No Water / Grit | Safe Operation | Use On Live Pipeline | Silent

Videos

Induction Stripping

You can use this method to quickly remove coatings such as fiberglass liners, coal tar epoxy, chartek fireproofing and other coatings from steel surfaces.

It’s quiet and does not create any secondary waste.

Ebonite Disbonded From Interior of Pipe

Hard rubber is disbonded with induction heating, as a result it is chiseled away easily.

Certainly you can use Induction stripping to quickly remove coatings such as fiberglass liners, coal tar epoxy, chartek fireproofing and other coatings from steel surfaces. The process is quiet and does not create any secondary waste.

Pipeline Life Extension Project in Thailiand

Fast Coatings removal by means of induction heating. Coaltar Enamel removed quickly from live pipeline carrying gas. Induction disbonding was the preferred method due to simplicity, and cleanliness and relyability. Technip was the EPC