RPR Technologies AS, with their unique patented solutions is the world’s leading provider of tailored induction systems for coatings removal on steel.

Today it is used for many applications such as on marine vessels, buildings, power plants, bridges, tanks, oil processing industry, offshore platforms, pipelines, etc. Most noteworthy, the RPR Induction system is economic in use and can achieve removal rates more than twice as fast as traditional systems at lower energy consumption with no handling of grit or water.

RPR Technologies

RPR Technologies is a Norwegian based company has operated in the field of surface refurbishment on steel since 2002.

The company is located in Skien, south-west of Oslo from where they are operating its global business activities, comprising the manufacturing, sale and rental of induction coatings removal systems. RPR has established a world-wide network of professional distributors, offering local service and support.

Save money and reduce the impact on the environment with the RPR induction based coating remover

Coatings Removal by RPR Induction

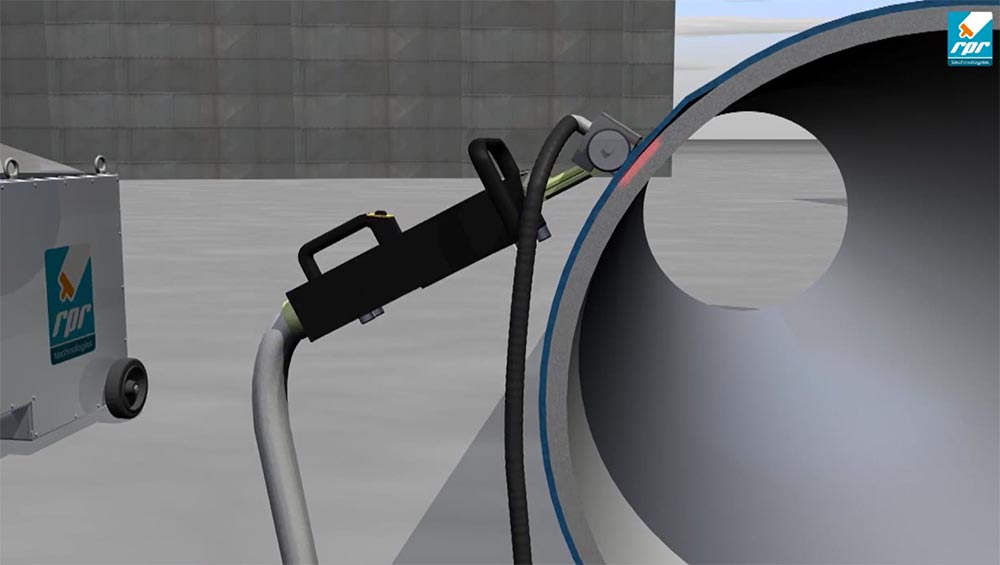

The induction technology operates by using a generator producing high frequency electric currents transferred to magnetic steel by moving an inductor head over the surface that results in a controlled and fast heating of the steel. After instantly heating the steel surface to 160-210 °C, coatings with thickness up to 20-25 mm can easily be scraped off in flakes or stripes. As a result, removal rates of 30 m2/hr or more can be achieved on even and easily accessible surfaces, depending on type of coatings, conditions and film thickness. The RPR induction system can remove most type of coatings like passive fire protection (PFP), glass-fiber coatings (GRP), reinforced epoxy, anti-skid (Epoxies), 3 LPE and thick rubber coatings.

The RPR system requires a minimum steel thickness of 4-5 mm to avoid damage on the backside coatings or insulation material used. In certain cases, a quick sweep blast may be necessary to achieve special requirements of the surface profile, specified by the coatings suppliers.

Environmentally friendly induction technology

Due to its unique environmentally friendly and efficient properties, RPR’s induction technology is used worldwide with a growing demand for many applications, replacing other traditional coatings removal methods such as chemicals, abrasives or water-jetting (UHP). In contrast to other competitive methods this controlled induction method produces low levels of fumes, no airborne particle emissions and no contaminated water or sand. It is virtually noiseless and gives a safer working environment for the operators and co-workers.

According to the Norwegian National Institute of Technology, the typical energy consumption of the induction system is 25-30% to that of abrasive blasting or UHP water-jetting.

Efficient coatings removal and reduced waste handling

While the RPR induction technology can be used on most paints and coatings, it is particularly efficient on thick and resilient systems where one would have to use large quantities of grit or water, or even chisel to remove otherwise. Easy containment and no contaminated deposits of sand or water make induction not only practical on tough surfaces but also for removal of coatings containing hazardous substances like asbestos, lead or PCB. Unlike blasting methods, induction does not break the coating into small particles, but it rather comes off in strips and flakes for easy bagging and containment.

RPR Induction is Cost efficient

With a minimum of power consumption even the thickest and hardest coatings must surrender.

- The Induction Disbonder is up to 10 times faster than conventional methods.

- Work day and night shifts without disturbing the neighbours.

- Plug & Play. Compact unit that is easy to bring and install -anywhere.

- Minimum wear & tear.

Environmentally friendly

The Induction Disbonder removes asbestos, lead and toxic coatings without compromising the health of the operators nor the environment.

- No dust. No noise.

- 75 % energy reduction.

- Minimum waste management.

- An excellent safety record.

Health, security & environment

Contractors and facility owners will appreciate the opportunity to work without disturbing and contaminating with dust and noise:

- on bridges in city centers and river crossings.

- In areas of power plants, control rooms and confined spaces.

- On offshore installations, cut expensive sand/grit and fresh water logistics.

- On pipelines that cross protected and sensitive nature.